SYMATESE launches SYMATESE LAB

A science based company

The science of tissue regeneration and reconstruction combined with administration systems in 4 areas of expertise

4 domains of expertise with focus on tissue regeneration

Therapeutics, aesthetics, cosmetics and administration systems

Patients safety comes first

Serving physicians and patients for over 25 years, covering more than 15 therapeutic domains. Leveraging our technology platform: collagen, hyaluronic acid, silicones and thermoplastics.

OUR MISSION

We imagine, design, and produce the best technological solutions, to give anatomical structures the means to regenerate, to repair yourself naturally.

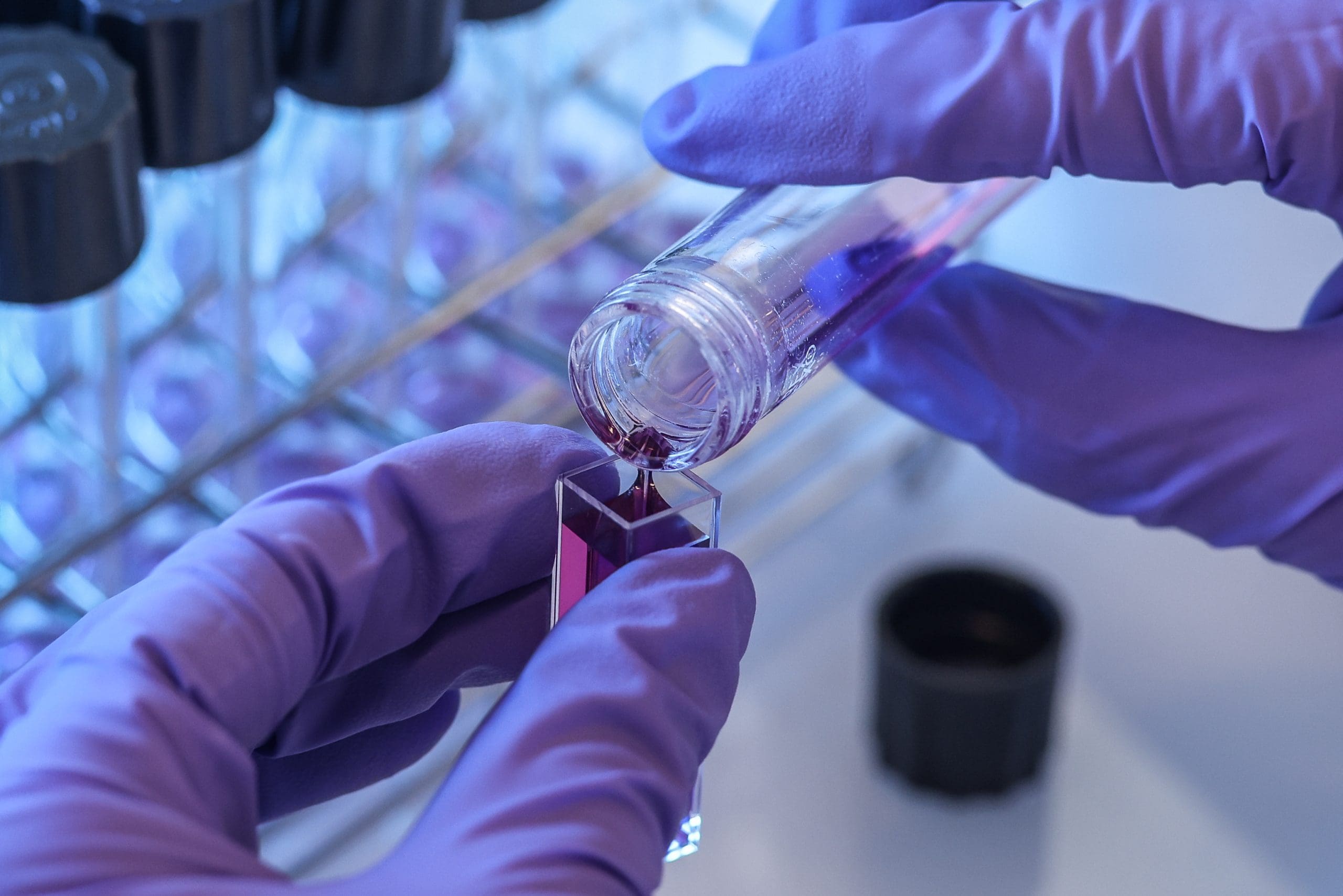

4 areas of expertise

THERAPEUTIC TISSUE REGENERATION

The cornerstone of our research, plays a fundamental and pioneering role in particular in the science of the skin.

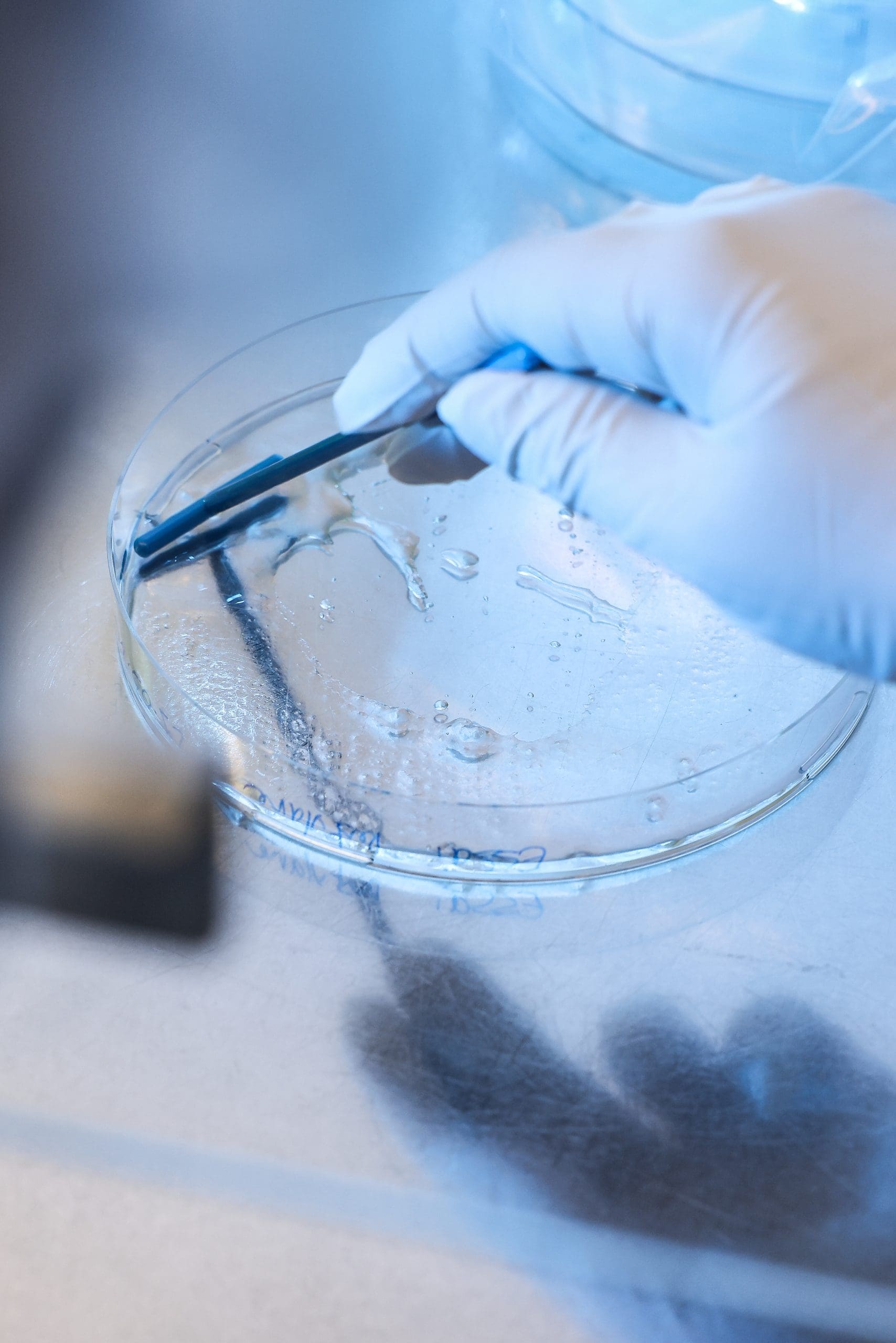

TISSUE REGENERATION AT THE SERVICE OF COSMETICS

Strengthened end of 2021 with L'ORÉAL partnership in the field of tissue regeneration.

Initiated with Collagen matrices for in vitro tissue reconstruction.

AESTHETIC MEDICINE AND SURGICAL RECONSTRUCTION

Developed from our expertise in the field of THERAPEUTICS and SKIN SCIENCE with PRYME® TECHNOLOGY by SYMATESE™ for breast implants and C-HA PURE TECHNOLOGY by SYMATESE™, for HA-based dermal fillers.

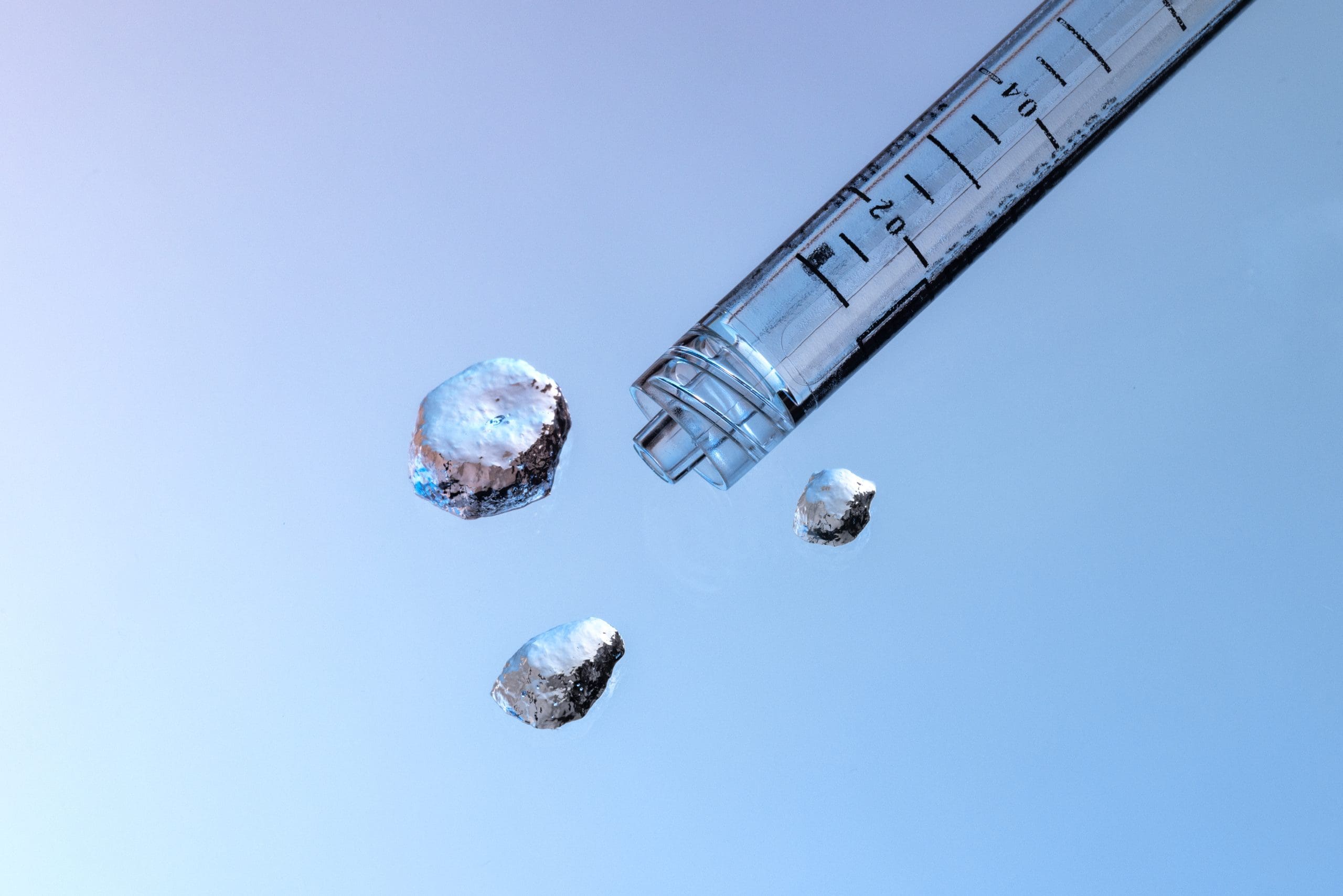

DELIVERY SYSTEMS

Ability to make tailor-made, perfectly adapted to therapeutic and aesthetic indications.

Combination solutions, unique on the market [syringe + gel] for aesthetic and ophthalmological indications.

Million patients per year

+

0

Medical specialties

0

Continents

0

Brand partners

+

0

our ecosystem

+15 medical specialties

Burn treatment, Cardiovascular surgery, Maxillofacial surgery, Orthopaedics, Plastic and reconstructive surgery, Spine surgery, Dental surgery, Dermatology, Imaging (MRI), Ophthalmic surgery, Urology, Wound healing, Rheumatology, Aesthetic medicine, Aesthetic plastic surgery.

Partners include

BIOTECH DENTAL, BVI, EPISKIN, EVOLUS, JOHNSON & JOHNSON, GALDERMA, L’ORÉAL, MEDTRON, URGO, VYGON

Thermoplastics

Plastic injection molding allows us to supply a wide variety of polymers widely used in the manufacture of medical devices allowing to develop and produce different delivery systems: high-tech syringes, emergency devices, injectors and their components.